Reflections on China's Transformation of the Car Industry, Part B: Lure Tesla to set up factories in China and Learn

Learning from the best.

Agile software development, rooted in Lean car manufacturing principles, emerged during a pivotal revolution in the 1980s. Now, we are witnessing another, much greater, transformation in the automotive industry—one that may offer valuable lessons. In this series:

Part A: The Disruptions

Part B: Lure Tesla to set up factories in China and Learn

Part D: Traditional Car Manufacturers Reluctant to Evolve 👎🏾

Part F: Lacking on Plan B and C 👎🏾

Part G: Acknowledge Mistakes

The word “Lure” was not imagined by me, this CNBC report used it.

Telsa pioneered EV. In my opinion, the recent success of Chinese EVs is closely tied to Tesla’s manufacturing operations in Shanghai (called Gigafactory), which began in 2019.

The Chinese government offered Tesla numerous benefits, incentives, and even exclusive compromises.

“Unique among foreign automakers in China, the plant is wholly owned by Tesla and not operated as a joint venture with a Chinese company, the first time the government had allowed such an arrangement.”

“Tesla received US$521 million in loans from Chinese banks at favorable interest rates, and US$82 million in grant funding.”

“The local Shanghai government granted Tesla a corporate income tax rate of 15% for 2019 through 2023, compared to the typical 25% rate in China”

- source: Wikipedia

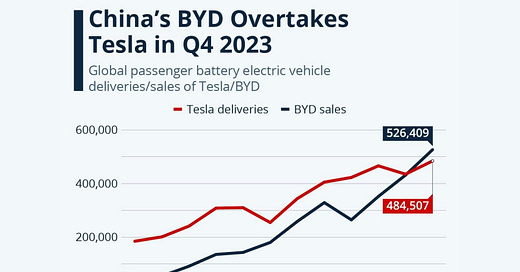

Looking back, the Communist Chinese government was shrewd and played a long game, and it paid off only a few years later. I think Elon Musk probably would regret this decision, as Tesla is facing tough competition from Chinese EV brands right now.

After Tesla began manufacturing in China—a massive investment—it's inevitable that Elon Musk would gradually concede to the Chinese government's requests, such as increasing the proportion of local Chinese suppliers (which, frankly, is not unreasonable).

This is the same strategy the Chinese government used in the 1980s when it lured Volkswagen to manufacture traditional cars in Shanghai. A decade later, Chinese car brands began to emerge.

However, this time, China totally changed the game with EV.

The electric vehicle (EV) market is a new frontier compared to traditional cars, with far fewer suppliers—around several dozens versus hundreds. This is why China's EV industry grew so rapidly, as Chinese suppliers learned and mastered the necessary skills and processes through their collaboration with Tesla.

The technological advantages that traditional car manufacturers like BMW developed over decades, such as expertise in internal combustion engines (ICE), became irrelevant in the EV market.

The numerous new EV companies in China essentially copied the successful formula of design, production pipeline, and testing from the best—Tesla—and leveraged the following two advantages:

1. Government support

Chinese EVs have greatly benefited from substantial government industrial policy support over the past few years, with these subsidies only gradually tapering off this year. (The current US and Europe tariff hike on Chinese imported EVs, IMO, is justified. However, again, they acted too late)

2. Relative Cheap Labour

There are no unions really in China. Chinese workers are hard-working (and earn lower wages compared to their Western counterparts) and Elon Musk praised this multiple times.

However, when the skilled workers and engineers who had worked at Tesla's Gigafactory for years started accepting offers from Chinese EV factories, it raised the question of whether Elon Musk was too overly confident in attributing Tesla's success to advanced full self-driving capability and his personal management style. (the fact: not many people would use full self-driving anyway).

Lesson

Setting aside my dislike for the current Chinese political system (led by the Communist Party), their willingness to learn from the best is an admirable trait that solopreneurs can benefit from adopting.

However, this is often easier said than done. In the software industry, how often do you see a CEO or CIO humble enough to seek external help and put the company into a learning mode? Probably not very often, right?

Here is a rare example,

The No.1 reason that LinkedIn could achieve "daily production releases” is “Luring a Google veteran to implement automated testing”.

I witnessed this kind of rare and courageous act from management back in 2005. Our business director brought in two ThoughtWorks consultants as Agile coaches to overhaul our development process. At the time, many staff were sceptical (Agile was still a relatively new concept in Australia). However, it turned out to be a tremendous success. That experience also marked my introduction to end-to-end test automation, real continuous integration, and Ruby—thanks to one of the Agile coaches. (Yes, true Agile coaches emphasize the importance of E2E test automation.)

Related reading:

What Happened to ThoughtWorks?

(My No.1 article on Medium, in terms of reads and likes).